Search from website

Search from website

Home CRDMO Services Quality Control

Icosagen offers a broad range of tailored services for the development and production of recombinant antibodies, including complex antibody formats.

Though the challenge is with the latter, as many hard-to-express antigens also require very customized approach to purification and storage buffer formulation. For each step Icosagen has highly qualified personnel focused on solving any challenges.

Recombinant antibody production services includes the possibility to change antibody subtype or host specificity, and to generate various types of antibodies, such as human IgG1, IgG2, IgG4, mouse IgG1, IgG2a, IgG2b, IgG3, rat IgG1, IgG2a, rabbit IgG, chicken IgY, chimeric antibodies, antibody fragments, single chain molecules, bispecific antibodies (bi- scFV-Fc, DVD-Ig, Crossmabs), etc.

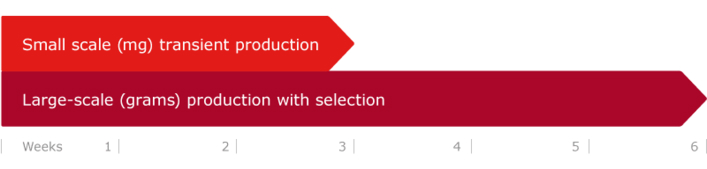

is used to deliver up to hundreds of milligrams of purified antibody within 3-4 weeks starting from vector cloning.

is used to scale up the production volumes up to 40 liters cost effectively, and to deliver multiple gram quantities of purified antibody. In this case, also episomal production cell bank can be generated, which allows to omit transfection completely when repetitive and constant supply of the same antibody is required with consistent reproducibility.

Synthesis of variable region DNA

Expression vector construction

Transfection and expression analysis

Timescale: 1 week if cDNA is available, 4 weeks if variable regions need to be synthesized

Deliverables: Expression/secretion data 48h transfection

Antibiotic selection. Production volume scale-up

Production cell bank generation

Protein production. Production analysis

Timescale: 3 weeks. In case of transient production (without selection and cell bank generation) — 1 week.

Deliverables: Antibody constaining supernatant, analysis data

Antibody purification

Antibody characterization

Timescale: 1 week

Deliverables: Purified antibody, QC data, characterisation data, detailed report